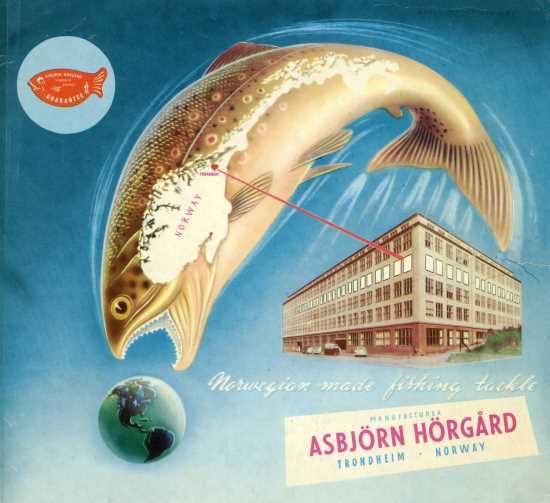

Asbjörn Hörgård

/ABU Rods

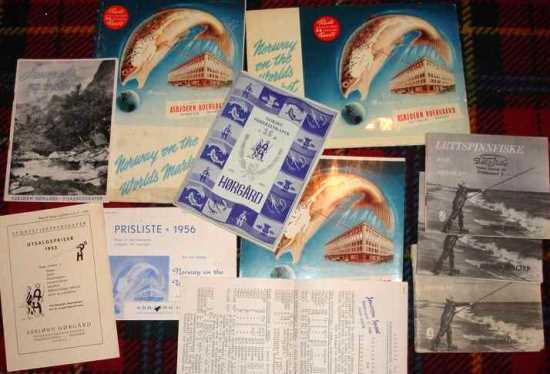

Composite Hörgård image and many others below from the very interesting vintage fishing web pages of Øyvind S. Bruland

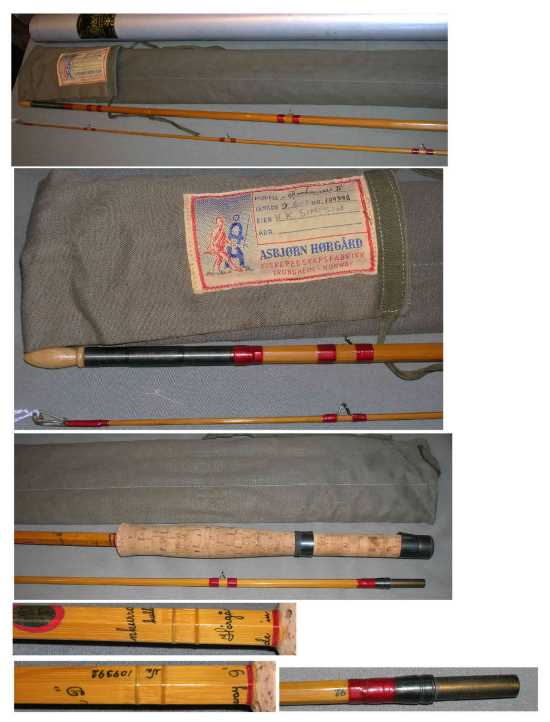

Missing from my collection was a Horgard split cane flyrod and spinning rod or baitcaster imported by ABU from Norway, until a few years ago.

Now arrived to my

collection, are two

Asbjørn

Hørgård

rods, (Konkurasse and Golden Fly) from Oyvind in Norway and Earl in

United States. Still looking for any baitcaster model viz Norsk or

Sjoa models or Spinning viz model Figga. The spinning Threadline

version has been found and is seen below.

When I realised Len Borgstroms first fly rod was a A.H.

Lillemor

(incidentally named after Asbjörns wife) , I searched to

find one and sent it his way and this is it on the carpet in his

study.

For

someone who personally, and with his family, gave so much to

the Sportfishing world, it was wonderful feeling indeed for me

to send a rod such as this back to him and bring so much joy to him,

that he now hangs it with pride in his home office. 1951 was a

special year for ABU to include these fine rods in the N&N

catalog of the era.

A.H. Threadline below (the most recently arrived addition)

A.H. Golden Fly below

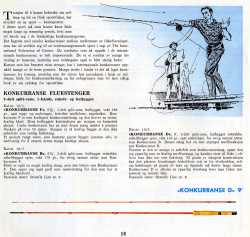

A.H. Konkurannse D (Tournament model) below

Oyvind Bruland has again recently been in contact with me and is offering further help to bring to the fore, more information about ABU/Asbjorn Horgard rods.

Here

Oyvind had previously shared images of the missing A.H. Threadline

spinning rod that I am missing. Hopefully I will be able to buy

rods such as these one day.

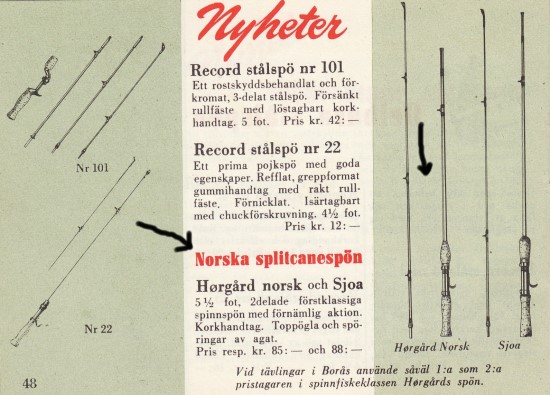

as well

as images of the missing A.H.Sjoa baitcasting rod from Dag

(first 2) and Oyvind (second 2)

My friend Ove in Norway is organising for me to get a A.H. Sjoa baitcasting rod, then just A.H.Norsk to locate.

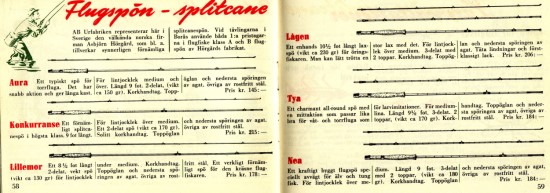

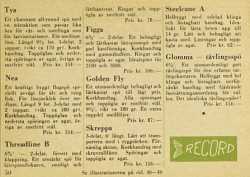

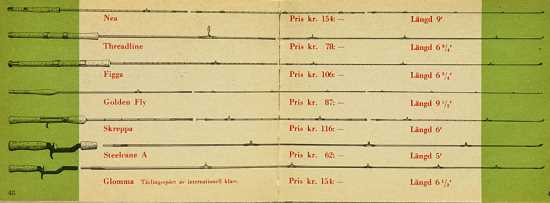

1951 Napp och Nytt

The

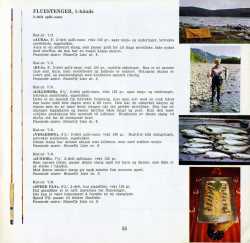

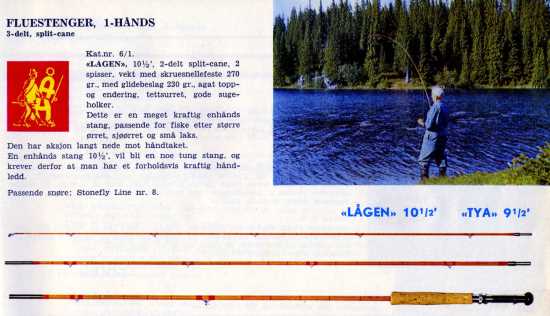

beautiful light flyrod A.H. Lagen with me and is shown below by

Oyvind. A user of vintage equipment, he assures me this rod

"is

the very nice sea-trout single-hand fly rod which came in three

sections and with two tops"

My Norwegian friend Jon Steinsnes and Dr Wolfram Schott are also helpful contributers and are on the job keeping their eyes open for one of these Horgard split cane Threadline spinning rods and/or baitcaster (Norske or Sjoa) rods for me.

Also Hans van der Pauw from the Netherlands has been a great help in gather information on the Horgard rods supplied to ABU.

Enjoy this summarizing Asbjørn Hørgård information written by Wolfram Schott

The Horgard story is extraordinary and well worth the read to see a story of pride, passion, persistence unfold to the benefit of all.

Wolfram has also supplied some wonderful images of the Horgard manufacturing equipment

Alas

there

is

no such thing as a Hörgaard Museum, not in Trondheim (where the

factory was), nor anywhere else in Norway. The items are exhibited

in the Norsk Skogsmuseum (Norwegian Forestry

Museum) in Elverum/Norway, some 400 miles south of Trondheim,

together with MANY hunting, fishing, lumbering, wood-processing and

other related items.

The Horgard rods commissioned by ABU are shown here in better detail than in their 50's catalog pages above.

Great translation from the Norwegian, allowing us English only speaking fans an insight into the background and process involved.

Many thanks to the shy and anonomous translater

In this

first

article,

I will

take

for

me

fly fishing

rods

for

trout

made

from

splitcane

It is

a

known fact

that

The rods

for

trout fishing

with

fly

gear,

were

produced

a few

places

in the country.

Making

cane

rods requires

special

knowledge

and

special

machine equipment,

which

was not

easily

obtainable.

Some

handful of

useful

and

ardent

amateur

team sticks

of wood and

delivered

to a

small

circle.

In

By

splitting

up

The adhesive

was a mixture

of

horn glue

and varnishes.

He noticed

that

the quality

of the

glue

and

paint

were not good,

and

worked his way

to

The rods

achieved a

good

reputation.

They

were

tested

by

city experts

in

fly fishing,

Director Reidar

Brekke

in

Trondheim Insurance

company.

He

was the

most

famous and

important angler

in the city.

He

started

throwing

competitions

in

The statements

from

Brekke

weighed

heavily

and

increased

demand

for Hørgårds

rods.

But

to

sell

them

in

In1944,

Hørgård

went to prison

cause

he

had

been

active

some time

in

an

underground

group in

After the war, there was steady increase in production volume and more than 130,000 fly rods are totally manufactured in Asbjørn Hørgårds name. Until about 1970, the cane rods were dominating the market, when in terms of quality rods for fly fishing. After this the company started fiberglass, carbon and Boro rods of high quality. At this time there was no industrial mass production of cane rods at Hørgård.

The rods were made of a combination of craftsmanship and use of special equipment and appliances. A brief description of the manufacturing method follows here:

Bamboo

was imported

from

These must be stored in longer time before they can be used.

They must

be

really

dry.

The production

begins

with

selecting

and adapt

two

and

two

sticks

in order

to

eliminate weakness

in the

joints

of

the bamboo.

The fibres

in

bamboo

runner

from

extension

to

extension, and these

joints

must

be

dislodged

during

production of the

segments,

so

that the

two parts

never

are located

together.

The logs are

split

by a

knife.

The fibres must not be cut, because fibres can be a bit skewed. A knife will follow the fibres, which are parallel from extension to extension. A saw will cut the fibres and make the rod segment weak.

A

starting part

consists of

six

ribs, three

from

the one

bamboo

and

three

from

the

other.

These

ribs followed

each other

during

the entire

production process.

The

outermost

layer

of the

bamboo

stick,

it is strongest,

the

smooth

shiny

outer surface

must maintained,

the fibres

here

have

the greatest

flexibility.

Therefore

the ribs must be

planed

on the inside,

to keep the

strong

outer fibres.

The outer surface

joints

are smoothened lightly.

Then

the ribs are planed

equally thick throughout

its length.

This

dimension

is slightly

larger

than the

finished

rib

thickness

in

the

thickest end.

When

all the

ribs

are planed

equally

thick

with

a triangular

cross section,

it is ready for

the tapering

plan. Dimension

and

taper determines

the

type of

rod

that

is result.

This

cutting

is done

by machines.

The

self-produced

machines can be

set

exactly

to the

infinite

possibilities

of different

dimensions.

Thus

infinite many

different

types of

rods can be

produced.

After

this operation

is

completed,

six

and

six

ribs are laid

as they

were paired

from

the start.

Gluing

is done

so

that

the

six

ribs which

belong

together

are put into

a

glue container.

From there over

to

a

machine

where

two

threads

with

a

suitable

pressure

are placed

around

the ribs,

both ways

to prevent

twisting

of the

rod.

The bamboo joints are parted, thus

some

of the

weaknesses

from

these

joints is

eliminated.

After

gluing

the

rods are corrected.

When the

rods

are ready, they

must be

controlled

and

put on grips,

reel

mount,

rings

and

hook

ring,

then signed

and

finally

painted.

More to follow I'm sure....

If you have any others listed above, particularly a Horgard Baitcast split cane rod such as the Norsk or Sjoa, or Spinning models viz Figga that are unneeded or doubles in your collection and are available for a reasonable fee, I would be very pleased to hear from you. Particularly any Record rods or Diplomat series, or Safari Spinning or Fly rod and a Pacific Series boat rod.